Acoustical testing of QT on Nail-Laminated Timber

AUTHOR: Justin Reidling, Acoustical Engineer

As mass timber continues to hold the spotlight in sustainable design for wood floor-ceiling assemblies and other building elements, the industry continues to sort out the (architectural) details. In a recent acoustical test series, we took a closer look at nail-laminated timber and its sound transfer characteristics.

Nail-laminated timber (NLT) is a mass timber construction consisting of dimensional lumber turned on edge and nailed – or sometimes screwed – together to make a panel. Because it’s made of dimensional lumber, it can be fabricated on-site for great construction-schedule flexibility and local material sourcing.

Spoiler alert: in this testing, we do not see the international building code’s STC 50 & IIC 50 requirements, but we do learn some things about air paths, mass, and resilient building elements!

How does raw NLT perform?

In third party testing, the NLT (unsurprisingly) had some gaps that allowed us to see the receiver room from the source room! That kind of weakness in the base assembly showed itself in the data, as the assembly achieved STC 28, IIC 26, and HIIC 25. * An airtight assembly would have performed better.

Can that be better?

We added QT sound control underlayment. QT is composed of 94% recycled material and is suitable as an underlayment for tile, wood, laminate, LVT and carpet finish floors.

In this testing, we started with a layer of QTscu 4012 below a layer of plywood. This QT & plywood “raft” immediately increased the standardized ratings to STC 32, IIC 36, and HIIC 37.

QT typically does not provide a big benefit to airborne sound isolation (STC ratings), but this case is a clear exception. QT, although not air-impermeable and not particularly massive, was able to add a large amount of acoustical impedance to the see-through air gaps in the NLT. This boosted the STC rating.

The increases in the IIC and HIIC are not surprising, since impact isolation is what QT does best. It helps to decouple the impact surface (finish flooring) and the structure. We further note that HIIC saw greater gains than IIC. This is also unsurprising, because QT does great work in the mid and high frequencies of sound.

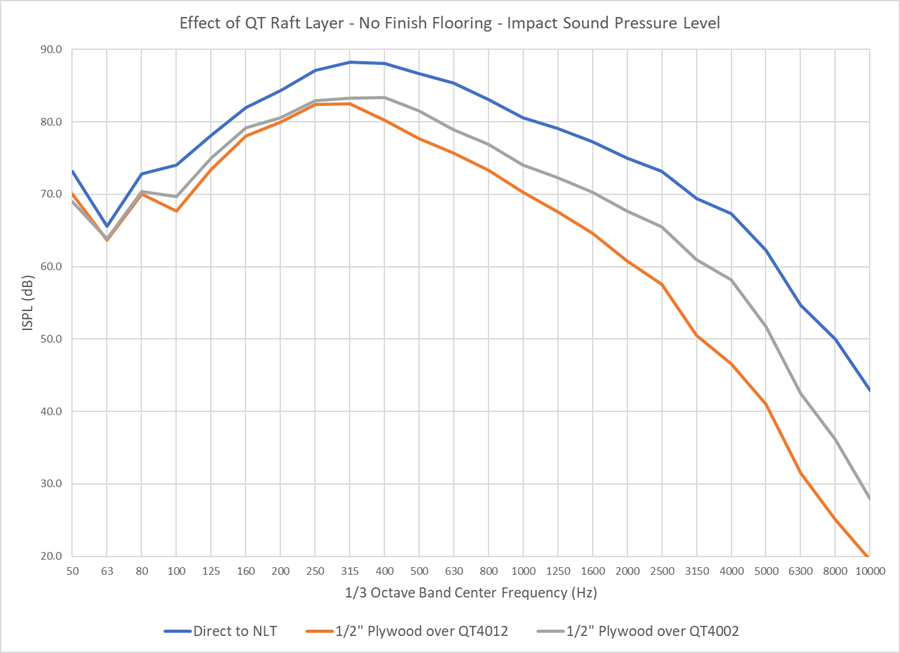

Changing out the layer of 12 mm QT4012 for a layer of only 2 mm QT4002 is also helpful, but less so, achieving STC 30, IIC 32, and HIIC 32. Consider the chart (higher ISPL is louder):

Here’s a full breakdown of the test series:

QT4012 raft layer unless otherwise noted.

We can see that the greatest benefit comes from adding the finish flooring with underlayment, and adding thickness to the underlayment is helpful but with diminishing returns.

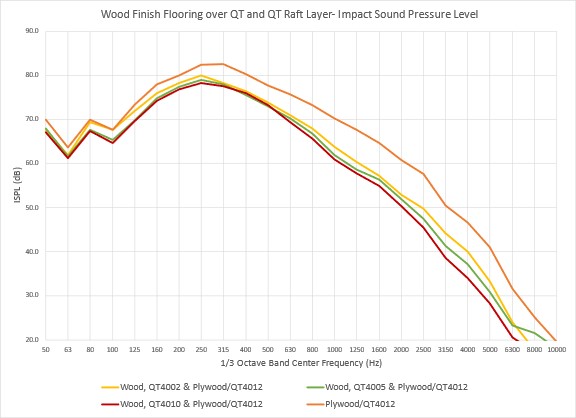

Here’s a chart showing how the impact sound changes with frequency among the engineered wood build-ups:

What else can be done to improve the sound isolation performance of NLT?

Common strategies include:

Concrete topping pour – Adding a whole lot of mass on top of the NLT helps attenuate sound at frequencies across the spectrum.

Isolated concrete topping pour – Add a resilient layer below the concrete, such as QTrbm for additional benefit. In this test series, we had a plywood “topping,” which was not as massive, and it shows.

Ceiling – Add a ceiling below the NLT; loose a lot of aesthetic value and gain a whole bunch of acoustic performance!

If you would like to learn more about this test series, testing on other mass timber assemblies, or other structural systems, don’t hesitate to reach out to us at https://www.qtsoundcontrol.com/sample-requests

Footnote:

* High-Frequency Impact Insulation Class (HIIC) – A single-number rating of a floor ceiling assembly defined in ASTM E3222 that describes the high-frequency impact noise reduction of the impact of hard-heeled shoes, dragging furniture, dog toenails, and dropping objects. Increasing ratings correspond with increasing performance. Think: "tap", "click"